-

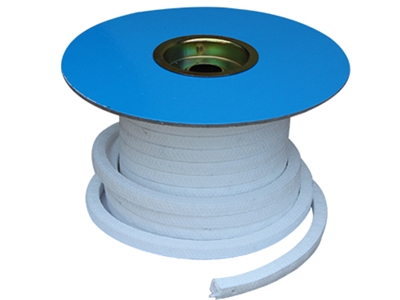

Pure PTFE Packing with oil is an economical and practical sealing material that combines the excellent properties of PTFE with the advantages of silicone oil impregnation. It features low friction, corrosion resistance, and high linear speed compatibility. Widely used for sealing valves, pumps, mixers, and other equipment, it is compatible with most media and is an ideal choice for industries such as chemical, petroleum, food, and pharmaceuticals

Pure PTFE Packing with oil is an economical and practical sealing material that combines the excellent properties of PTFE with the advantages of silicone oil impregnation. It features low friction, corrosion resistance, and high linear speed compatibility. Widely used for sealing valves, pumps, mixers, and other equipment, it is compatible with most media and is an ideal choice for industries such as chemical, petroleum, food, and pharmaceuticals -

PTFE Packing with Aramid Corner is made of aramid yarns impregnated with PTFE, while the friction faces are made of pure PTFE yarns. This structure enhances the lubrication ability of aramid fiber and improves the strength of the pure PTFE. This unique multi-wire braiding technology enhances both lubricity and tensile strength, significantly extending service life in demanding applications.

PTFE Packing with Aramid Corner is made of aramid yarns impregnated with PTFE, while the friction faces are made of pure PTFE yarns. This structure enhances the lubrication ability of aramid fiber and improves the strength of the pure PTFE. This unique multi-wire braiding technology enhances both lubricity and tensile strength, significantly extending service life in demanding applications. -

PTFE Filament Packing is made of sintered, highly stretched PTFE multifilament yarns reinforced with secondary PTFE emulsion impregnation. It features Structural Density, excellent Vibration Damping, 30-50% longer Dynamic Seal Lifespan compared to traditional Pure PTFE Packing. PTFE Filament packing is ideal for replacing traditional asbestos-based or aramid braided packing, enhancing sealing reliability while complying with environmental regulations.

PTFE Filament Packing is made of sintered, highly stretched PTFE multifilament yarns reinforced with secondary PTFE emulsion impregnation. It features Structural Density, excellent Vibration Damping, 30-50% longer Dynamic Seal Lifespan compared to traditional Pure PTFE Packing. PTFE Filament packing is ideal for replacing traditional asbestos-based or aramid braided packing, enhancing sealing reliability while complying with environmental regulations. -

Graphite PTFE Packing with Aramid Fiber Corner is a high-performance composite sealing material. It utilizes PTFE-impregnated aramid fibers as corner reinforcement, combined with high-quality graphite PTFE(black PTFE) yarn as the main sealing body, processed through a specialized braiding technique. This structure retains the high strength of aramid fibers while integrating the low friction, corrosion resistance, and excellent thermal conductivity of graphite PTFE, making it ideal for dynamic sealing in high-speed, high-pressure, and highly corrosive conditions

Graphite PTFE Packing with Aramid Fiber Corner is a high-performance composite sealing material. It utilizes PTFE-impregnated aramid fibers as corner reinforcement, combined with high-quality graphite PTFE(black PTFE) yarn as the main sealing body, processed through a specialized braiding technique. This structure retains the high strength of aramid fibers while integrating the low friction, corrosion resistance, and excellent thermal conductivity of graphite PTFE, making it ideal for dynamic sealing in high-speed, high-pressure, and highly corrosive conditions