-

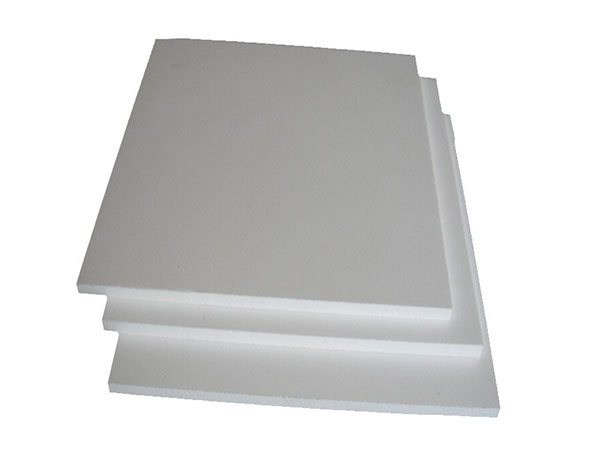

Modified PTFE sheets improved performance over conventional PTFE, Reduced product loss, and emissions. Excellent bolt torque retention, unique manufacturing process minimizes cold flow problems typical of skived and expanded PTFE Sheets. Withstands a wide range of chemicals for extended service life in a wide variety of applications.

Modified PTFE sheets improved performance over conventional PTFE, Reduced product loss, and emissions. Excellent bolt torque retention, unique manufacturing process minimizes cold flow problems typical of skived and expanded PTFE Sheets. Withstands a wide range of chemicals for extended service life in a wide variety of applications. -

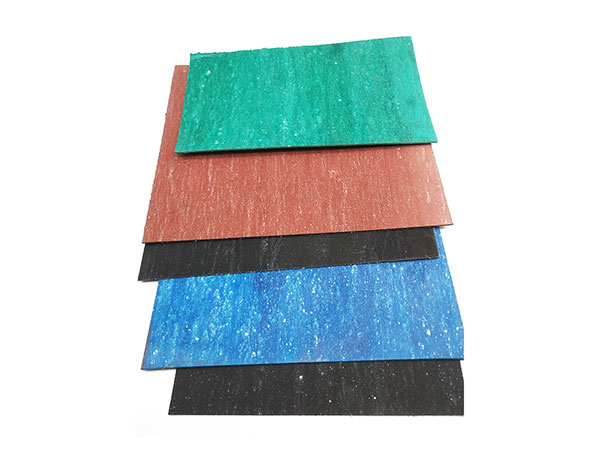

The non-asbestos compressed sheet is made from aramid/kevlar fiber, natural rubber, heat-resisting packing material, and dye, compressed and calendered under high temperature and pressure into a sheet form. It eliminates the asbestos-rubber sheet essentially and thoroughly. Substitution of corresponding models of asbestos rubber sheet, Used for the equipment in water, high-temperature steam, compressed air, valve, heat exchanger etc. and used as sealing material in the joints of the pipeline. It can be used in the food and medical industry

The non-asbestos compressed sheet is made from aramid/kevlar fiber, natural rubber, heat-resisting packing material, and dye, compressed and calendered under high temperature and pressure into a sheet form. It eliminates the asbestos-rubber sheet essentially and thoroughly. Substitution of corresponding models of asbestos rubber sheet, Used for the equipment in water, high-temperature steam, compressed air, valve, heat exchanger etc. and used as sealing material in the joints of the pipeline. It can be used in the food and medical industry -

PTFE Bonded EPDM gasket is produced with high-quality EPDM rubber and PTFE for maximum chemical and corrosion resistance. They are suitable for fiberglass, glass-lined, and steel full-face flanges. The gaskets have Low bolt torque with superior sealing, Dual, Concentric, Convex sealing rings; They will eliminate cracked flanges, reducing installation costs, while maintaining high performance. It is ideal for plastic piping systems, as well as metal or plastic-lined metal systems. Standards: ASME (ANSI) B16.5, JIS 10K, DIN2501 PN10/PN16, SABS1123, BS4504 etc

PTFE Bonded EPDM gasket is produced with high-quality EPDM rubber and PTFE for maximum chemical and corrosion resistance. They are suitable for fiberglass, glass-lined, and steel full-face flanges. The gaskets have Low bolt torque with superior sealing, Dual, Concentric, Convex sealing rings; They will eliminate cracked flanges, reducing installation costs, while maintaining high performance. It is ideal for plastic piping systems, as well as metal or plastic-lined metal systems. Standards: ASME (ANSI) B16.5, JIS 10K, DIN2501 PN10/PN16, SABS1123, BS4504 etc -

PTFE Filament Packing is made of sintered, highly stretched PTFE multifilament yarns reinforced with secondary PTFE emulsion impregnation. It features Structural Density, excellent Vibration Damping, 30-50% longer Dynamic Seal Lifespan compared to traditional Pure PTFE Packing. PTFE Filament packing is ideal for replacing traditional asbestos-based or aramid braided packing, enhancing sealing reliability while complying with environmental regulations.

PTFE Filament Packing is made of sintered, highly stretched PTFE multifilament yarns reinforced with secondary PTFE emulsion impregnation. It features Structural Density, excellent Vibration Damping, 30-50% longer Dynamic Seal Lifespan compared to traditional Pure PTFE Packing. PTFE Filament packing is ideal for replacing traditional asbestos-based or aramid braided packing, enhancing sealing reliability while complying with environmental regulations. -

PTFE Packing with Aramid Corner is made of aramid yarns impregnated with PTFE, while the friction faces are made of pure PTFE yarns. This structure enhances the lubrication ability of aramid fiber and improves the strength of the pure PTFE. This unique multi-wire braiding technology enhances both lubricity and tensile strength, significantly extending service life in demanding applications.

PTFE Packing with Aramid Corner is made of aramid yarns impregnated with PTFE, while the friction faces are made of pure PTFE yarns. This structure enhances the lubrication ability of aramid fiber and improves the strength of the pure PTFE. This unique multi-wire braiding technology enhances both lubricity and tensile strength, significantly extending service life in demanding applications. -

Pure PTFE Packing is a pure PTFE fiber yarn braided into the square cross-section and impregnated with PTFE dispersion. High cross-sectional density and structural strength. It is designed for valves and lower shaft speed application under medial pressure in food processing, pharmaceuticals, paper mills, fiber plants where high purity and corrosion resistance is required. PTFE packing can be also treated with lubrication, it is an economic type.

Pure PTFE Packing is a pure PTFE fiber yarn braided into the square cross-section and impregnated with PTFE dispersion. High cross-sectional density and structural strength. It is designed for valves and lower shaft speed application under medial pressure in food processing, pharmaceuticals, paper mills, fiber plants where high purity and corrosion resistance is required. PTFE packing can be also treated with lubrication, it is an economic type. -

Pure PTFE Packing with oil is an economical and practical sealing material that combines the excellent properties of PTFE with the advantages of silicone oil impregnation. It features low friction, corrosion resistance, and high linear speed compatibility. Widely used for sealing valves, pumps, mixers, and other equipment, it is compatible with most media and is an ideal choice for industries such as chemical, petroleum, food, and pharmaceuticals

Pure PTFE Packing with oil is an economical and practical sealing material that combines the excellent properties of PTFE with the advantages of silicone oil impregnation. It features low friction, corrosion resistance, and high linear speed compatibility. Widely used for sealing valves, pumps, mixers, and other equipment, it is compatible with most media and is an ideal choice for industries such as chemical, petroleum, food, and pharmaceuticals -

PTFE Rod has Extruded or Molded two types. Molded/Extruded PTFE Rod produced from 100% PTFE virgin PTFE materials, it has the lowest coefficient of friction of all kinds of solid materials and the best electrical properties of all plastics. They are the ideal elements for the food industry. PTFE tube made from 100% PTFE virgin PTFE material, it is suitable for use as machining stock for all kinds of chemical, electrical, mechanical components

PTFE Rod has Extruded or Molded two types. Molded/Extruded PTFE Rod produced from 100% PTFE virgin PTFE materials, it has the lowest coefficient of friction of all kinds of solid materials and the best electrical properties of all plastics. They are the ideal elements for the food industry. PTFE tube made from 100% PTFE virgin PTFE material, it is suitable for use as machining stock for all kinds of chemical, electrical, mechanical components -

Pure PTFE Yarn is used to braid Pure PTFE Packing, available with Pure PTFE Yarn and PTFE Yarn with oil two types. Other yarns for braid packing are available, such as graphite yarn, GFO yarn, Ramie Yarn, Acrylic yarn, Kevlar Yarn, Carbon fiber yarn, Glass /Ceramic fiber and asbestos yarn etc Raw materials.

Pure PTFE Yarn is used to braid Pure PTFE Packing, available with Pure PTFE Yarn and PTFE Yarn with oil two types. Other yarns for braid packing are available, such as graphite yarn, GFO yarn, Ramie Yarn, Acrylic yarn, Kevlar Yarn, Carbon fiber yarn, Glass /Ceramic fiber and asbestos yarn etc Raw materials.