-

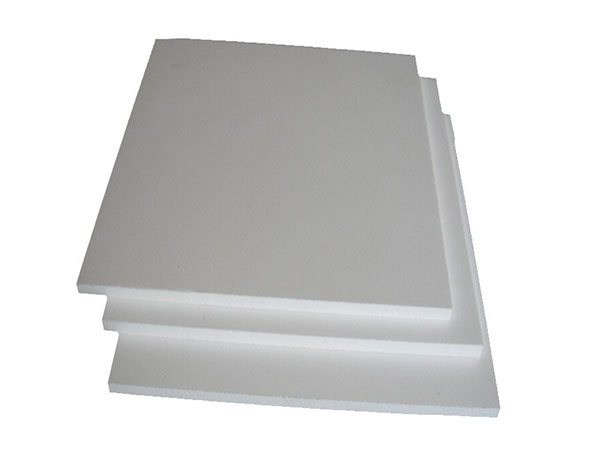

Modified PTFE sheets improved performance over conventional PTFE, Reduced product loss, and emissions. Excellent bolt torque retention, unique manufacturing process minimizes cold flow problems typical of skived and expanded PTFE Sheets. Withstands a wide range of chemicals for extended service life in a wide variety of applications.

Modified PTFE sheets improved performance over conventional PTFE, Reduced product loss, and emissions. Excellent bolt torque retention, unique manufacturing process minimizes cold flow problems typical of skived and expanded PTFE Sheets. Withstands a wide range of chemicals for extended service life in a wide variety of applications. -

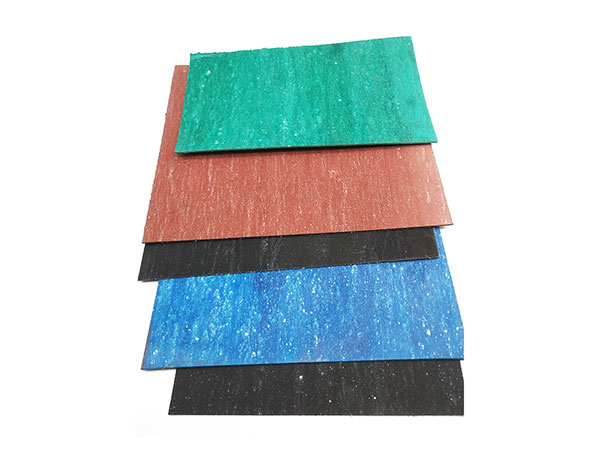

The non-asbestos compressed sheet is made from aramid/kevlar fiber, natural rubber, heat-resisting packing material, and dye, compressed and calendered under high temperature and pressure into a sheet form. It eliminates the asbestos-rubber sheet essentially and thoroughly. Substitution of corresponding models of asbestos rubber sheet, Used for the equipment in water, high-temperature steam, compressed air, valve, heat exchanger etc. and used as sealing material in the joints of the pipeline. It can be used in the food and medical industry

The non-asbestos compressed sheet is made from aramid/kevlar fiber, natural rubber, heat-resisting packing material, and dye, compressed and calendered under high temperature and pressure into a sheet form. It eliminates the asbestos-rubber sheet essentially and thoroughly. Substitution of corresponding models of asbestos rubber sheet, Used for the equipment in water, high-temperature steam, compressed air, valve, heat exchanger etc. and used as sealing material in the joints of the pipeline. It can be used in the food and medical industry -

PTFE Bonded EPDM gasket is produced with high-quality EPDM rubber and PTFE for maximum chemical and corrosion resistance. They are suitable for fiberglass, glass-lined, and steel full-face flanges. The gaskets have Low bolt torque with superior sealing, Dual, Concentric, Convex sealing rings; They will eliminate cracked flanges, reducing installation costs, while maintaining high performance. It is ideal for plastic piping systems, as well as metal or plastic-lined metal systems. Standards: ASME (ANSI) B16.5, JIS 10K, DIN2501 PN10/PN16, SABS1123, BS4504 etc

PTFE Bonded EPDM gasket is produced with high-quality EPDM rubber and PTFE for maximum chemical and corrosion resistance. They are suitable for fiberglass, glass-lined, and steel full-face flanges. The gaskets have Low bolt torque with superior sealing, Dual, Concentric, Convex sealing rings; They will eliminate cracked flanges, reducing installation costs, while maintaining high performance. It is ideal for plastic piping systems, as well as metal or plastic-lined metal systems. Standards: ASME (ANSI) B16.5, JIS 10K, DIN2501 PN10/PN16, SABS1123, BS4504 etc -

PTFE Filament Packing is made of sintered, highly stretched PTFE multifilament yarns reinforced with secondary PTFE emulsion impregnation. It features Structural Density, excellent Vibration Damping, 30-50% longer Dynamic Seal Lifespan compared to traditional Pure PTFE Packing. PTFE Filament packing is ideal for replacing traditional asbestos-based or aramid braided packing, enhancing sealing reliability while complying with environmental regulations.

PTFE Filament Packing is made of sintered, highly stretched PTFE multifilament yarns reinforced with secondary PTFE emulsion impregnation. It features Structural Density, excellent Vibration Damping, 30-50% longer Dynamic Seal Lifespan compared to traditional Pure PTFE Packing. PTFE Filament packing is ideal for replacing traditional asbestos-based or aramid braided packing, enhancing sealing reliability while complying with environmental regulations. -

PTFE Packing with Aramid Corner is made of aramid yarns impregnated with PTFE, while the friction faces are made of pure PTFE yarns. This structure enhances the lubrication ability of aramid fiber and improves the strength of the pure PTFE. This unique multi-wire braiding technology enhances both lubricity and tensile strength, significantly extending service life in demanding applications.

PTFE Packing with Aramid Corner is made of aramid yarns impregnated with PTFE, while the friction faces are made of pure PTFE yarns. This structure enhances the lubrication ability of aramid fiber and improves the strength of the pure PTFE. This unique multi-wire braiding technology enhances both lubricity and tensile strength, significantly extending service life in demanding applications. -

Pure PTFE Packing is a pure PTFE fiber yarn braided into the square cross-section and impregnated with PTFE dispersion. High cross-sectional density and structural strength. It is designed for valves and lower shaft speed application under medial pressure in food processing, pharmaceuticals, paper mills, fiber plants where high purity and corrosion resistance is required. PTFE packing can be also treated with lubrication, it is an economic type.

Pure PTFE Packing is a pure PTFE fiber yarn braided into the square cross-section and impregnated with PTFE dispersion. High cross-sectional density and structural strength. It is designed for valves and lower shaft speed application under medial pressure in food processing, pharmaceuticals, paper mills, fiber plants where high purity and corrosion resistance is required. PTFE packing can be also treated with lubrication, it is an economic type. -

Pure PTFE Packing with oil is an economical and practical sealing material that combines the excellent properties of PTFE with the advantages of silicone oil impregnation. It features low friction, corrosion resistance, and high linear speed compatibility. Widely used for sealing valves, pumps, mixers, and other equipment, it is compatible with most media and is an ideal choice for industries such as chemical, petroleum, food, and pharmaceuticals

Pure PTFE Packing with oil is an economical and practical sealing material that combines the excellent properties of PTFE with the advantages of silicone oil impregnation. It features low friction, corrosion resistance, and high linear speed compatibility. Widely used for sealing valves, pumps, mixers, and other equipment, it is compatible with most media and is an ideal choice for industries such as chemical, petroleum, food, and pharmaceuticals -

PTFE Rod has Extruded or Molded two types. Molded/Extruded PTFE Rod produced from 100% PTFE virgin PTFE materials, it has the lowest coefficient of friction of all kinds of solid materials and the best electrical properties of all plastics. They are the ideal elements for the food industry. PTFE tube made from 100% PTFE virgin PTFE material, it is suitable for use as machining stock for all kinds of chemical, electrical, mechanical components

PTFE Rod has Extruded or Molded two types. Molded/Extruded PTFE Rod produced from 100% PTFE virgin PTFE materials, it has the lowest coefficient of friction of all kinds of solid materials and the best electrical properties of all plastics. They are the ideal elements for the food industry. PTFE tube made from 100% PTFE virgin PTFE material, it is suitable for use as machining stock for all kinds of chemical, electrical, mechanical components -

Pure PTFE Yarn is used to braid Pure PTFE Packing, available with Pure PTFE Yarn and PTFE Yarn with oil two types. Other yarns for braid packing are available, such as graphite yarn, GFO yarn, Ramie Yarn, Acrylic yarn, Kevlar Yarn, Carbon fiber yarn, Glass /Ceramic fiber and asbestos yarn etc Raw materials.

Pure PTFE Yarn is used to braid Pure PTFE Packing, available with Pure PTFE Yarn and PTFE Yarn with oil two types. Other yarns for braid packing are available, such as graphite yarn, GFO yarn, Ramie Yarn, Acrylic yarn, Kevlar Yarn, Carbon fiber yarn, Glass /Ceramic fiber and asbestos yarn etc Raw materials. -

Ramie Fiber packing is made of high-quality ramie fiber, impregnated with light-colored, special PTFE and lubricant during square plaiting operation.it is not harsh on shafts and stems. It is widely used for kinds of pumps, refinery equipment, filters, valves, etc. It is also available with Ramie fiber packing with silicon rubber core,high-elasticity silicone core absorbs vibration, improves sealing, and controls leakage.

Ramie Fiber packing is made of high-quality ramie fiber, impregnated with light-colored, special PTFE and lubricant during square plaiting operation.it is not harsh on shafts and stems. It is widely used for kinds of pumps, refinery equipment, filters, valves, etc. It is also available with Ramie fiber packing with silicon rubber core,high-elasticity silicone core absorbs vibration, improves sealing, and controls leakage. -

Ring Joint Gaskets are machined from a variety of types forged solid metal such as Soft iron, ANSI304, ANSI316, F5, Low carbon, and special materials of alloy metals, Inconel Duplex, Monel, Hastelloy, Titanium, etc. They are designed for high pressure and temperature applications by selecting the suitable shape and material. The hardness of the RTJ gasket body should always be 20-30HB less than the hardness of the flanges to prevent flange deformation.

Ring Joint Gaskets are machined from a variety of types forged solid metal such as Soft iron, ANSI304, ANSI316, F5, Low carbon, and special materials of alloy metals, Inconel Duplex, Monel, Hastelloy, Titanium, etc. They are designed for high pressure and temperature applications by selecting the suitable shape and material. The hardness of the RTJ gasket body should always be 20-30HB less than the hardness of the flanges to prevent flange deformation. -

We have plenty of experience to produce many types of Rubber Parts by OEM or ODM, such as seals flinger, wiper, rubber hood latch, rubber bumper, seal drum, latch hood rubber, Gland half packing, and so on. They are mainly used as replacement applications for all industries. We could custom-produce accordingly to the drawings or samples.

We have plenty of experience to produce many types of Rubber Parts by OEM or ODM, such as seals flinger, wiper, rubber hood latch, rubber bumper, seal drum, latch hood rubber, Gland half packing, and so on. They are mainly used as replacement applications for all industries. We could custom-produce accordingly to the drawings or samples. -

Rubber sheets are manufactured for your different requirements such as oil-resisting, acid, and alkali-resisting, cold and heat-resisting, insulation, anti-seismic, etc. They can cut into various gaskets, used in chemicals, elections, fire-resisting, and food. They also can be used as a sealer, buffer rubber ring, rubber mat, sealing strip, and for the decoration of flights of step and ground of hotel, port boats, and ships, vehicles, etc. The materials are available in various kinds such as NBR, SBR, EPDM, Silicone, NR, Viton, etc.

Rubber sheets are manufactured for your different requirements such as oil-resisting, acid, and alkali-resisting, cold and heat-resisting, insulation, anti-seismic, etc. They can cut into various gaskets, used in chemicals, elections, fire-resisting, and food. They also can be used as a sealer, buffer rubber ring, rubber mat, sealing strip, and for the decoration of flights of step and ground of hotel, port boats, and ships, vehicles, etc. The materials are available in various kinds such as NBR, SBR, EPDM, Silicone, NR, Viton, etc. -

Spiral Wound Gasket consists of a thin metal hoop and non-metallic filler material that is simultaneously wound. The metal hoop is pre-formed in V or W-shaped profile, which allows the gasket to act as a spring between the flanges. Spiral Wound Gaskets are extremely popular due to the wide variety of available styles and sizes, it is the precision-engineered solution for flange joints, manholes, and other high-temperature, high-pressure applications. We can produce according to ASME, BS, JIS, and EN(DIN) standards or client requests.

Spiral Wound Gasket consists of a thin metal hoop and non-metallic filler material that is simultaneously wound. The metal hoop is pre-formed in V or W-shaped profile, which allows the gasket to act as a spring between the flanges. Spiral Wound Gaskets are extremely popular due to the wide variety of available styles and sizes, it is the precision-engineered solution for flange joints, manholes, and other high-temperature, high-pressure applications. We can produce according to ASME, BS, JIS, and EN(DIN) standards or client requests.