-

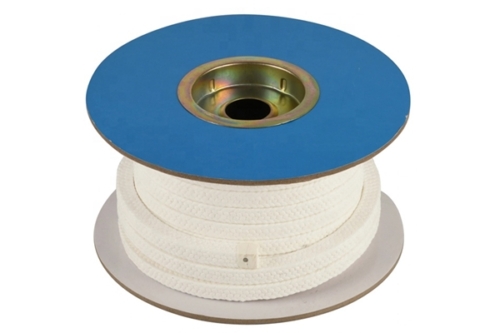

Acrylic PTFE Packing is braided from high strength acrylic synthetic yarns with PTFE impregnated twice. The Acrylic PTFE packing has excellent properties of tightness, lubricity, and good resistance to chemicals. Wide variety of uses throughout a plant. Used in pumps and valves, it can handle most chemicals except strong acid, strong alkali, and a strong oxidizer. Especially for the condition of middle temperature, high pressure, high speed, and where contamination is not permitted.

Acrylic PTFE Packing is braided from high strength acrylic synthetic yarns with PTFE impregnated twice. The Acrylic PTFE packing has excellent properties of tightness, lubricity, and good resistance to chemicals. Wide variety of uses throughout a plant. Used in pumps and valves, it can handle most chemicals except strong acid, strong alkali, and a strong oxidizer. Especially for the condition of middle temperature, high pressure, high speed, and where contamination is not permitted. -

Aramid PTFE Packing braided from high-quality Aramid(Kevlar)yarns which are uniformly impregnated with PTFE dispersion. The braided packing shows good chemical resistance, high elasticity, and very low cold flow. It is wear-resistant but may damage the shaft if not used properly. The aramid fiber can be braided in many types for different applications, such as Aramid PTFE Packing with lubricant for a slurry service application, Spun aramid fiber packing with economical use; PTFE packing with Aramid corner, Graphite PTFE Packing with Aramid Corner, GPTFE & Aramid in Zebra braided packing, etc.

Aramid PTFE Packing braided from high-quality Aramid(Kevlar)yarns which are uniformly impregnated with PTFE dispersion. The braided packing shows good chemical resistance, high elasticity, and very low cold flow. It is wear-resistant but may damage the shaft if not used properly. The aramid fiber can be braided in many types for different applications, such as Aramid PTFE Packing with lubricant for a slurry service application, Spun aramid fiber packing with economical use; PTFE packing with Aramid corner, Graphite PTFE Packing with Aramid Corner, GPTFE & Aramid in Zebra braided packing, etc. -

Carbonized fiber packing is braided from oxidized PAN fiber impregnated with PTFE, silicon-oil-free. Compared with traditional carbonized fiber packing, it is not brittle and suitable for high peripheral speed applications. With the high strength and good thermal conductivity of the PAN fiber, and excellent self-lubrication of the PTFE, the packing has a long life and does not damage shafts. The related carbon fiber packing for a different purpose is available, such as Carbonized fiber packing with graphite, Carbonized Fiber Packing Reinforced with Nickel wire, Carbon fiber packing.

Carbonized fiber packing is braided from oxidized PAN fiber impregnated with PTFE, silicon-oil-free. Compared with traditional carbonized fiber packing, it is not brittle and suitable for high peripheral speed applications. With the high strength and good thermal conductivity of the PAN fiber, and excellent self-lubrication of the PTFE, the packing has a long life and does not damage shafts. The related carbon fiber packing for a different purpose is available, such as Carbonized fiber packing with graphite, Carbonized Fiber Packing Reinforced with Nickel wire, Carbon fiber packing. -

Ceramic fiber braided packing rope is made from high-quality ceramic fiber, it has excellent capabilities of high strength and high-temperature resistance. Ceramic fiber is a standout among the different organic and inorganic fibers as an ideal replacement of asbestos, it has excellent capabilities of high strength and high-temperature resistance. Ceramic Fiber Packing can be impregnated with graphite or insert with steel wire

Ceramic fiber braided packing rope is made from high-quality ceramic fiber, it has excellent capabilities of high strength and high-temperature resistance. Ceramic fiber is a standout among the different organic and inorganic fibers as an ideal replacement of asbestos, it has excellent capabilities of high strength and high-temperature resistance. Ceramic Fiber Packing can be impregnated with graphite or insert with steel wire -

Expanded Graphite packing is braided from low-sulfur expanded graphite yarns reinforced by cotton, glass fiber, etc. It has very low friction, and does not damage shafts or stems. It shows good thermal and chemical resistance and high elasticity. Expanded graphite packing can be reinforced with Inconel wire, SS wire, nickel wire, and other metal materials to improve mechanical strength.

Expanded Graphite packing is braided from low-sulfur expanded graphite yarns reinforced by cotton, glass fiber, etc. It has very low friction, and does not damage shafts or stems. It shows good thermal and chemical resistance and high elasticity. Expanded graphite packing can be reinforced with Inconel wire, SS wire, nickel wire, and other metal materials to improve mechanical strength. -

Glass fiber packing is ideal organic and inorganic fiber as a replacement of asbestos. It is braided from E-glass fiber impregnated with PTFE. The packing has many excellent characteristics such as high strength, high-temperature resistance, low density, low thermal conductivity, good insulation, and non-ignitibility, etc. Glass fiber packing without any impregnation and Glass fiber packing impregnated with graphite are also available.

Glass fiber packing is ideal organic and inorganic fiber as a replacement of asbestos. It is braided from E-glass fiber impregnated with PTFE. The packing has many excellent characteristics such as high strength, high-temperature resistance, low density, low thermal conductivity, good insulation, and non-ignitibility, etc. Glass fiber packing without any impregnation and Glass fiber packing impregnated with graphite are also available. -

Graphite PTFE (gPTFE) braided packing, also known as Black PTFE Packing, is a high-performance sealing material made from braided PTFE yarn uniformly embedded with graphite particles. Its versatility and reliability make it an excellent choice for demanding sealing applications. and it is designed to provide exceptional sealing performance in demanding industrial applications.

Graphite PTFE (gPTFE) braided packing, also known as Black PTFE Packing, is a high-performance sealing material made from braided PTFE yarn uniformly embedded with graphite particles. Its versatility and reliability make it an excellent choice for demanding sealing applications. and it is designed to provide exceptional sealing performance in demanding industrial applications. -

Graphite PTFE Packing with Aramid Fiber Corner is a high-performance composite sealing material. It utilizes PTFE-impregnated aramid fibers as corner reinforcement, combined with high-quality graphite PTFE(black PTFE) yarn as the main sealing body, processed through a specialized braiding technique. This structure retains the high strength of aramid fibers while integrating the low friction, corrosion resistance, and excellent thermal conductivity of graphite PTFE, making it ideal for dynamic sealing in high-speed, high-pressure, and highly corrosive conditions

Graphite PTFE Packing with Aramid Fiber Corner is a high-performance composite sealing material. It utilizes PTFE-impregnated aramid fibers as corner reinforcement, combined with high-quality graphite PTFE(black PTFE) yarn as the main sealing body, processed through a specialized braiding technique. This structure retains the high strength of aramid fibers while integrating the low friction, corrosion resistance, and excellent thermal conductivity of graphite PTFE, making it ideal for dynamic sealing in high-speed, high-pressure, and highly corrosive conditions -

Kynol Fiber Packing Braided (also called GOLDEN Packing) is a high-performance sealing material made from Kynol™ (Novilid™ or Phenolic™) fibers and impregnated with PTFE lubricant. This material combines excellent mechanical properties, flexibility, and strength, making it suitable for various industrial applications.

Kynol Fiber Packing Braided (also called GOLDEN Packing) is a high-performance sealing material made from Kynol™ (Novilid™ or Phenolic™) fibers and impregnated with PTFE lubricant. This material combines excellent mechanical properties, flexibility, and strength, making it suitable for various industrial applications. -

PTFE Filament Packing is made of sintered, highly stretched PTFE multifilament yarns reinforced with secondary PTFE emulsion impregnation. It features Structural Density, excellent Vibration Damping, 30-50% longer Dynamic Seal Lifespan compared to traditional Pure PTFE Packing. PTFE Filament packing is ideal for replacing traditional asbestos-based or aramid braided packing, enhancing sealing reliability while complying with environmental regulations.

PTFE Filament Packing is made of sintered, highly stretched PTFE multifilament yarns reinforced with secondary PTFE emulsion impregnation. It features Structural Density, excellent Vibration Damping, 30-50% longer Dynamic Seal Lifespan compared to traditional Pure PTFE Packing. PTFE Filament packing is ideal for replacing traditional asbestos-based or aramid braided packing, enhancing sealing reliability while complying with environmental regulations. -

PTFE Packing with Aramid Corner is made of aramid yarns impregnated with PTFE, while the friction faces are made of pure PTFE yarns. This structure enhances the lubrication ability of aramid fiber and improves the strength of the pure PTFE. This unique multi-wire braiding technology enhances both lubricity and tensile strength, significantly extending service life in demanding applications.

PTFE Packing with Aramid Corner is made of aramid yarns impregnated with PTFE, while the friction faces are made of pure PTFE yarns. This structure enhances the lubrication ability of aramid fiber and improves the strength of the pure PTFE. This unique multi-wire braiding technology enhances both lubricity and tensile strength, significantly extending service life in demanding applications. -

Pure PTFE Packing is a pure PTFE fiber yarn braided into the square cross-section and impregnated with PTFE dispersion. High cross-sectional density and structural strength. It is designed for valves and lower shaft speed application under medial pressure in food processing, pharmaceuticals, paper mills, fiber plants where high purity and corrosion resistance is required. PTFE packing can be also treated with lubrication, it is an economic type.

Pure PTFE Packing is a pure PTFE fiber yarn braided into the square cross-section and impregnated with PTFE dispersion. High cross-sectional density and structural strength. It is designed for valves and lower shaft speed application under medial pressure in food processing, pharmaceuticals, paper mills, fiber plants where high purity and corrosion resistance is required. PTFE packing can be also treated with lubrication, it is an economic type. -

Pure PTFE Packing with oil is an economical and practical sealing material that combines the excellent properties of PTFE with the advantages of silicone oil impregnation. It features low friction, corrosion resistance, and high linear speed compatibility. Widely used for sealing valves, pumps, mixers, and other equipment, it is compatible with most media and is an ideal choice for industries such as chemical, petroleum, food, and pharmaceuticals

Pure PTFE Packing with oil is an economical and practical sealing material that combines the excellent properties of PTFE with the advantages of silicone oil impregnation. It features low friction, corrosion resistance, and high linear speed compatibility. Widely used for sealing valves, pumps, mixers, and other equipment, it is compatible with most media and is an ideal choice for industries such as chemical, petroleum, food, and pharmaceuticals -

Ramie Fiber packing is made of high-quality ramie fiber, impregnated with light-colored, special PTFE and lubricant during square plaiting operation.it is not harsh on shafts and stems. It is widely used for kinds of pumps, refinery equipment, filters, valves, etc. It is also available with Ramie fiber packing with silicon rubber core,high-elasticity silicone core absorbs vibration, improves sealing, and controls leakage.

Ramie Fiber packing is made of high-quality ramie fiber, impregnated with light-colored, special PTFE and lubricant during square plaiting operation.it is not harsh on shafts and stems. It is widely used for kinds of pumps, refinery equipment, filters, valves, etc. It is also available with Ramie fiber packing with silicon rubber core,high-elasticity silicone core absorbs vibration, improves sealing, and controls leakage.