PTFE Packing with Aramid Corner is made of aramid yarns impregnated with PTFE, while the friction faces are made of pure PTFE yarns. This structure enhances the lubrication ability of aramid fiber and improves the strength of the pure PTFE. This unique multi-wire braiding technology enhances both lubricity and tensile strength, significantly extending service life in demanding applications.

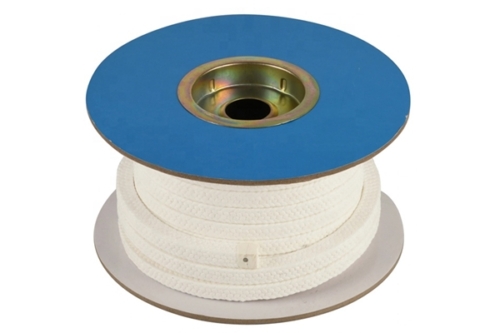

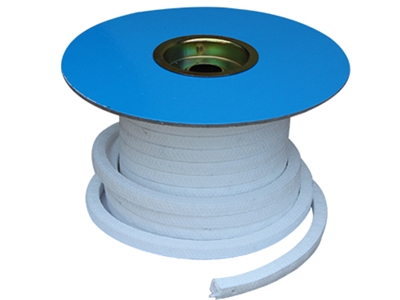

PTFE Packing With Aramid Corner

Description

PTFE packing with aramid corner features a hybrid construction and zebra-stripe braiding, the braided packing has wear resistance & dynamic sealing stability.

It has the following advantages: High Pressure & Speed Tolerance – Designed for reciprocating pumps (≤25MPa) & medium-speed centrifugal pumps (≤10m/s).

Contamination-Free – Meets hygiene standards for pharmaceutical, food, and sugar industries.

Chemical Resistance – Handles steam, gases, solvents, mild acids/alkalis, and abrasive media

Easy Maintenance – Quick installation/removal without shaft damage.

Technical Parameter:

| Pressure | Rotating | 20 bar |

| Reciprocating | 100 bar | |

| Static | 180 bar | |

| Shaft speed | 12 m/s | |

| Density | 1.4g/cm3 | |

| Temperature | -100~+2800C | |

| PH range | 2~12 | |

Application

Fluid Handling – Valves, compressors, and agitators in chemical/petrochemical plants.

Clean Industries – Paper mills, drug manufacturing, food processing (no fiber shedding).

Abrasive Media – Pumps handling ash slurry, wastewater, or corrosive powders.

High-Vibration Zones – Silicone-core versions for mixers, plunger pumps, and diesel engines.