Description

| Pressure |

Rotating |

30bar |

| Reciprocating |

160 bar |

| Static |

280 bar |

| Shaft speed |

12 m/s |

| Density |

1.4g/cm3 |

| Temperature |

-150~+2800C |

| PH range |

0~14 |

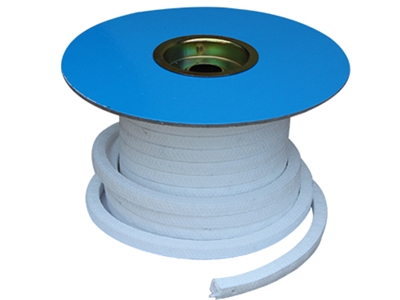

PACKAGE: In coils of 5 or 10 kg, other weights on request. A box for each coil, 20 kgs per carton.

Feature

Structural Design: High-density braiding, compact cross-section, excellent dimensional stability, strong resistance to compression and extrusion

Chemical Resistance: Resistant to all chemicals except molten uranium salts, including strong acids, alkalis, and organic solvents.

Eco-Safety: 100% asbestos-free, extremely low water absorption (<0.01%), clean and non-contaminating.

Friction Control: PTFE dispersion layer significantly reduces friction, minimizing wear and leakage risks

Application

Valve Sealing: Globe valves, needle valves, safety injection system valves

Pump System: Low-speed shaft pumps, plunger pumps

Chemical Processing: Acid/alkali fluid transfer, reactor agitator shafts

Precision Control: Contamination-sensitive environments (e.g., pharmaceutical, food-grade equipment)