Description

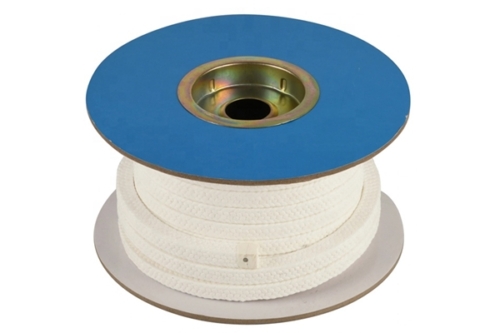

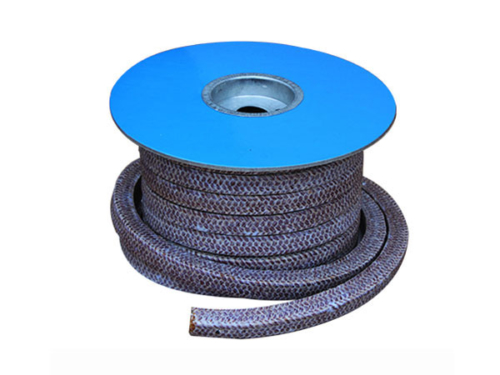

Aramid PTFE packing is an interlocked, square-braided product made from Kevlar aramid fibers impregnated with PTFE dispersion and specially treated with a silicone-based compound for quick and easy break-in. Aramid fiber offers a unique combination of properties: High Tensile strength& chemical resistance, Lasting Resilience, Low Thermal Expansion, and Low Coefficient of Friction. The Aramid PTFE packing is a robust and versatile solution for demanding industrial environments, offering exceptional strength, chemical resistance, and durability. its unique properties make it ideal for handling abrasive and high-temperature media while ensuring long service life and ease of maintenance.

| Rotating |

Reciprocating |

Static |

| Pressure |

25 bar |

100 bar |

200 bar |

| Shaft speed |

25 m/s |

1.5 m/s |

|

| Temperature |

-100~+280°C |

| PH range |

2~12 |

| Density |

1.3-1.4g/cm3 |

Application

Aramid Fiber Packing Applications:

General-Purpose Packing: Widely used in various industrial fields, including chemical, petroleum refining, pharmaceutical, food, sugar, paper, and power industries.

Durable and Reliable: Suitable for abrasive media containing solid particles.

Recommended for: Superheated steam, solvents, liquefied gases, syrups, and other abrasive fluids.

Temperature Resistance: Can be used in hot water up to 160°C without the need for cooling fluid.

Versatile Usage: Can be used alone or combined with other braided packing materials, placed at both ends as anti-extrusion rings.