| Place of origin: | China |

| MOQ: | 1 pcs |

| Production capacity : | 20000-25000pcs/Month |

| Delivery time: | 3-5 days generally after getting the deposit |

| Package: Carton. | Or put in the plywood case for bulk quantity |

| Certificate: | ISO9001, API6A |

| Material: | Variety Metal such as stainless steel, alloy metal together with graphite, PTFE filler, etc |

| feature: | Best Sealing Materials for Flange&Pipe |

| Usage: | used in the flange sealing structure of petrochemical, chemical, electric power, and other industries |

Metallic gaskets are designed to withstand extreme temperatures, pressures, and chemical exposure. Available in standard and custom configurations, these sturdy metal washers are made of a wide range of materials to suit all types of process applications.

Looking for a product for your construction project? If you are looking for a specific product for a construction project, are engaged in piping system engineering specifications, or need any type of additional help, our engineering and construction team can help, no matter where you are located.

Corrugated Metal Gaskets

The corrugated metal gaskets can be direct replacements for spiral wound gaskets. It can eliminate inward buckling issues while creating a seal at moderate flange stresses. Corrugated metal is covered with graphite, ceramic, or PTFE layer. An additional finishing layer is applied depending on the requirements of the medium to be sealed. The gaskets with a soft layer on both sides are used in low-pressure applications in large diameter flue gas ducts at high temperatures

Double Jacketed Gasket

Double Jacketed Gasket is made from graphite, ceramic, non-asbestos, etc filler covered with a thin metal jacket, such as SUS304, SUS316, Carbon steel, copper, soft iron, etc. With excellent sealing performance, it can be used in sealing spots of pressure vessels, exchanger heat, condenser, plain hole, etc.

Kammprofile Gasket

Kammprofile gasket consists of a concentrically serrated solid metal core with a soft conformable sealing layer bonded to each face. The layer can be expanded graphite, PTFE, asbestos-free gasket sheeting material or some soft metal. It features excellent compressibility and good recovery characteristics. The gasket is mainly suited for vacuum and extremely high-pressure applications. It can be refurbished and reused and has better leak tightness than spiral wound gaskets.

Ring Joint Gasket

Ring Joint Gaskets are machined from a variety of types of forged solid metal such as Soft iron, ANSI304, ANSI316, F5, Low carbon, and special materials of alloy metals, Inconel Duplex, Monel, Hastelloy, Titanium, etc. They are designed for high pressure and temperature applications by selecting the suitable shape and material. The hardness of the RTJ gasket body should always be 20-30HB less than the hardness of the flanges to prevent flange deformation.

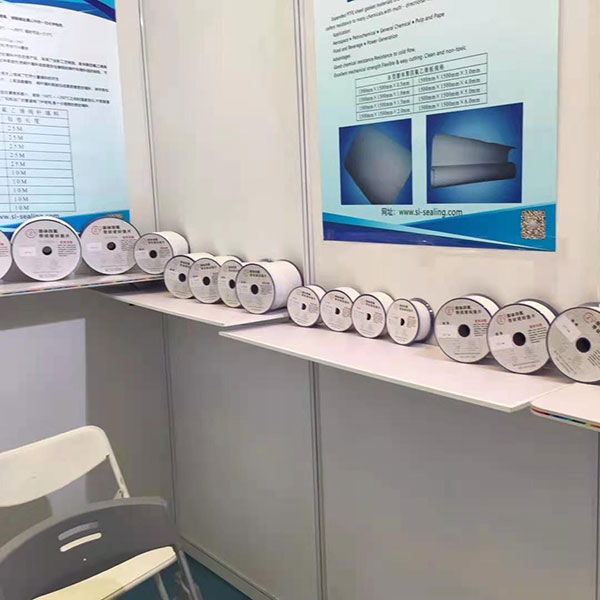

Spiral Wound Gasket

Spiral Wound Gasket (GS001) consists of the thin metal hoop and non-metallic filler material that is simultaneously wound. The metal hoop is pre-formed in V or W shaped profile, which allows the gasket to act as a spring between the flanges. Spiral Wound Gaskets are extremely popular due to the wide variety of available styles and sizes, it is the precision-engineered solution for flange joints, manholes, and other high-temperature, high-pressure applications. We can produce according to ASME, BS, JIS, and EN(DIN) standards or client requests.

Metallic Gaskets Manufacturers FAQ

Metallic Gaskets FAQ Guide

The metallic gasket is made of a single metal or a combination of metals, which makes the quality of its surface seal higher than that of non-metal similar products. In addition to enduring extreme temperatures and pressures, these gaskets are designed to withstand chemical exposures as well.

Metallic gaskets are usually a variety of ring joints, also called ring gaskets. Ring-type joint (RTJ) gasket is a common gasket in high-pressure environments in offshore oil and gas pipelines. With a strong metal ring structure, these gaskets are in different cross-sections, such as oval and octagonal. They can also provide a passage hole to allow pressure equalization on both sides of the sealing surface. These gaskets are sealed by initial line contact, creating a wedging effect between the gasket and the mating flange. The soft metal gasket exerts pressure on the sealing interface through the bolt force and flows into the fine structure of the harder matching flange to form a very tight and therefore very effective seal.

1. Metallic Gasket Material

Metallic gaskets can be produced in a variety of material combinations to suit all types of applications, such as heat exchangers, compressors, condensers, pumps, valves, and turbines. Here are some of the more popular metals and their performance characteristics.

| Material | Max T (F) |

Metals |

|---|---|---|

| Copper | 600 | Excellent for steam. Excellent chemical resistance except for powerful oxidizing agents. |

| Brass | 500 | Excellent for steam. Excellent chemical resistance except for powerful oxidizing agents. |

| GHL | 212 | Excellent chemical resistance except for powerful oxidizing agents. Available laminated or homogeneous. |

| Grafoil ® | 800 | Excellent chemical resistance except for powerful oxidizing agents. Available with 316 SS Foil, Mesh or Tang Core. Available laminated or homogeneous. |

| Titanium | 1000 | Similar in strength to 300 series stainless, but tougher and much less dense. Excellent resistance to chloride solutions (seawater) and bleaching solutions. |

| Soft Iron, Low Carbon Steel | 1000 | Soft. Will corrode in water. Mostly used were immersed in liquid hydrocarbons. |

| Stainless Steel, Type 304 |

1000 | A general-purpose, soft, corrosion-resistant, non-magnetic stainless that will not harden under heat. |

| Stainless Steel, Type 316 |

1000 | Not as strong as 304, but more corrosion-resistant in chemical solutions (except for a limited range of oxidising acids) |

| Stainless Steel, Type 321 |

1600 | Stronger than 304. Used when a similar performance to 304 is needed at higher temperatures. |

| Stainless Steel, Type 347 |

1600 | More corrosion-resistant and harder than 321. |

| Stainless Steel, Type 410 |

1200 | Commonly referred to as “Chrome”. This stainless will harden when heat-treated. It is highly magnetic, hard, and strong, but not very corrosion-resistant. |

| Stainless Steel, Type 430 |

1400 | More corrosion-resistant than 410, but will not harden when heat-treated. This stainless is soft and no stronger than 300 series stainless. |

| Nickel | 1400 | Exhibits good corrosion and erosion resistance at moderate temperatures. |

| Monel® | 1500 | A family of nickel/copper alloys that offer greater corrosion and erosion resistance than nickel alone. Particularly useful in seawater applications. |

| Inconel® | 2000 | A family of nickel/chromium alloys that are non-magnetic and take corrosion resistance to elevated temperatures. |

| Hastelloy® | 2000 | A family of Nickel/chromium/molybdenum alloys for use in highly aggressive chemical environments at elevated temper |

2. Types of Metallic Gasket

Actually, the metallic gasket can be mainly divided into a solid metallic gasket and a semi-metallic gasket.

1) Metallic Gaskets

Solid metal gaskets are used in applications where temperature and pressure do not allow the use of traditional gasket materials. Generally speaking, the gasket compression load needs to be high to deform the gasket, and the metal used for the gasket should be softer than the metal on the mating surface.

350

Flat solid: cut from sheet metal, these washers can be in unlimited sizes and shapes. The mating surface of the metal gasket needs to be perfectly aligned and flat to provide a good seal.

360

Abnormity and serration: A solid gasket with grooves on the surface helps to achieve a good seal under low seat stress. These models can be sheathed to protect the flange surface.

315

Corrugated: Made of thin metal, these gaskets provide sealing under low seat stress. They can be surface treated with ceramic, non-asbestos or flexible graphite, and can also be used with a PTFE shell.

2) Semi-metallic gasket

The semi-metallic gasket is suitable for high temperature, high pressure, and low-seat-stress applications. Mercer carries a large number of spiral wound gaskets in stainless steel with Grafoil, non-asbestos, or PTFE stock. We also provide all customized sizes and materials.

ElastaGraph: A corrugated liner, made of seamless flexible graphite, covering a metal core. The high-density inner ring increases sealing. Suitable for high temperature and high-pressure applications, with minimal valve seat stress.

Heavy-duty section: Proprietary high-pressure sealing system has a mating surface to match the ring of a specific section (API ring joint oval, octagonal, BX, RX; delta; lens; Bridgeman; round; etc.).

Sealing strip: used for heat exchangers, boilers, and condensers, these parts are welded together by multilayer metal nails.

Gasket: In order to be used as a gasket, we cut these parts into various shapes, sizes and metals.

With the ability to produce custom metal gaskets of almost any size, shape, or shape, Mercer provides high-performance metal gaskets and metal clamps for complex and demanding sealing applications (from heat exchangers, compressors, and condensers to pumps, valves, and turbines) The set of gasket solutions set the standard.

3. Application of Metallic Gasket

Metallic gaskets are used to seal applications with high temperatures and pressure, and non-asbestos materials will fail. Typical applications are heat exchangers, compressors, condensers, pumps, and valves. The following are some of the metal gasket applications, which can help you meet your specific metallic gasket needs.

1) Spiral wound gasket

It is made of alternately wound metal strips and soft filler materials, such as flexible graphite or polytetrafluoroethylene. Suitable for high-temperature and high-pressure occasions such as standard flanges, heat exchangers, boiler handholes, manholes, etc. There are many variations of this style, which can be made of many different metals and may have inner rings, outer rings, or both depending on the application.

2) Double Jacketed Gasket

The metal jacketed gasket, as the name suggests, consists of a metal shell and metal or non-metal compressed fiber filler. The packing material gives the gasket elasticity, while the metal sheath protects the packing and resists pressure, temperature and corrosion.

3) Ring Joint Gasket

The ring connection gasket is precision machined, and the metal gasket is suitable for high-pressure and high-temperature applications. They are manufactured in strict accordance with API 6A, API 17D, and ASME B16.20. These high-pressure gaskets come in various types, sizes, and material combinations.

4) KAMMPROFILE gasket

This style is made up of grooved metal cores with a layer of graphite or other composite materials on both sides. They are ideal for standard piping and heat exchanger applications. Kammprofile gaskets are available in 3 standard models: sealing ring, fixed guide ring, and floating guide ring.

5) Corrugated metal gasket (CMG)

Corrugated metal gaskets, or CMG for short, can be configured in several metals and various pitch grooves. These are machined flanges designed for low and medium-pressure applications.