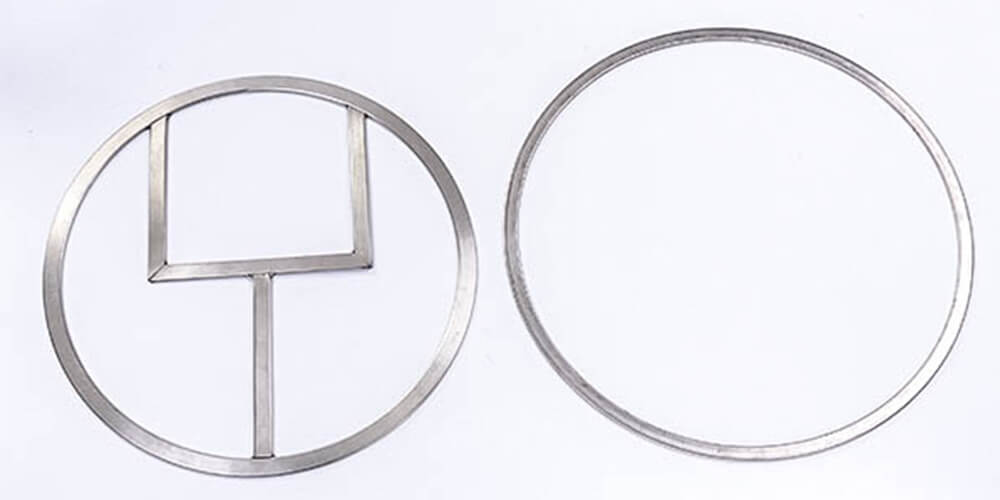

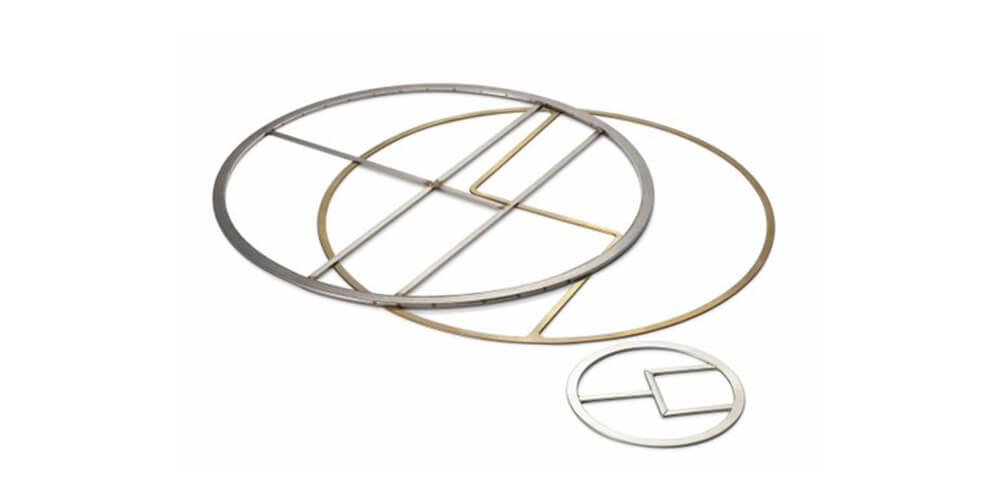

Custom Double Jacket Gasket

Double Jacketed Gasket is made from graphite, ceramic, non-asbestos, etc filler covered with a thin metal jacket, such as SUS304, SUS316, Carbon steel, copper, soft iron, etc.

With excellent sealing performance, it can be used in sealing spots of pressure vessels, exchanger heat, condenser, plain holes, etc.

Double jacketed gaskets have excellent sealing efficiency, provided by exerting strong pressure on circular rimes of the flanges, metal-jacketed gaskets can stand up to 30% deviation from the initial thickness, which is very useful in case of irregular or faulty flange rims. The chemical compatibility of the metal and the medium being sealed should be considered.

The filler material is completely enclosed by a two-piece metal jacket, which covers both the inside and outside diameters and both contact surfaces. It is designed for high pressure and temperature applications or where corrosion problems may exist with the filler being completely enclosed in a two-piece metal jacket.

| Metal material | DinMaterial No. | HardnessHB | Temperature (?) | Densityg/cm3 |

| CS/Soft Iron | 1.1003/1.0038 | 90~120 | -60~500 | 7.85 |

| SS304, SS304L | 1.4301/1.4306 | 130~180 | -250~550 | 7.9 |

| SS316, SS316L | 1.4401/1.4404 | 130~180 | -250~550 | 7.9 |

| Copper | 2.0090 | 50~80 | -250~400 | 8.9 |

| Aluminum | 3.0255 | 20~30 | -250~300 | 2.73 |

Other special metal Ti, Mon 400 is also available on request.

Double Jacket Gasket Manufacturers FAQ

1. What are double jacketed gaskets?

Double-jacketed gaskets are fully enclosed two-piece metal jackets covering the outer diameter, inner diameter, and two sealing surfaces. Widely used in heat exchanger applications for corrosive and high-temperature environments. Internal ribs (via partition bars) can be integral or welded, as in both types the primary seal is securely held.

2. What are the types of double jacketed gaskets?

There are three types of Double Jacketed Gaskets.

- Style 123: In Style 123 the filler material is completely enclosed by a two-piece metal jacket, which covers both the inside and outside diameters and both contact surfaces.

- Style 126: Style 126 is similar to Style 123 with the exception that the metal jacket is formed from a corrugated jacket providing better resilience than Style 123 since the The corrugations form multiple seals along the sealing face of the flange.

- Style 127: Style 127 is a double shell gasket constructed of two reversed wrap-round shells. It provides better flange support and handleability as well as better resistance to high pressures.

3. Why would I need a double jacketed gasket?

We use double-jacketed gaskets in high-pressure and high-temperature applications as they generally require a hard protective layer to resist blowouts. In addition, the jacketing feature protects the core layer from the above conditions.

4. What are the applications of double jacketed gaskets?

High-pressure and high-temperature applications require rigid gaskets with limited flange areas. They are also used in high load exhaust applications, heat exchangers, and pipe flange gasket connections. Equipment that uses Double Jacketed Gaskets includes:

- Heat exchangers

- Gas mains

- Boiler and fuls

- Pumps

- Valve bonnets

Those with simple shapes are applied in pipeline flange and sealing surface of internal-combustion machines, and those with complicated shapes are used in the flange cover of the heat exchanger, etc. The general gaskets are 10-25 MM wide and 2MM-8MM thick and can be used in a maximum work pressure of 6-10Mpa.

5. What are the advantages of double jacketed gaskets?

Double Jacketed Gaskets have many advantages which include:

- Filler material is protected by a metal jacket

- Ensures high elasticity and recovery.

- Filler material is protected by a metal jacket

- The welded construction of the bars results in two independent seals: the primary seal at the inner diameter and the secondary seal at the outer diameter.

6. What happens if you use the wrong type of gasket?

The good news is that not all gasket designs require a specific side up. If you’ve used gaskets in important places and you’ve done it wrong, you’ll know for sure. You may see some issues including leaking due to port alignment, crushing due to bolt issues, sticking if the coating is on the wrong side, etc.

If you flip the gasket over and still see the problem, you probably have a problem with the joint or gasket material being used. Talk to your trusted gasket material supplier. They may provide some insight into the problem you are having to help you troubleshoot.