Graphite PTFE Packing with Aramid Fiber Corner is a high-performance composite sealing material. It utilizes PTFE-impregnated aramid fibers as corner reinforcement, combined with high-quality graphite PTFE(black PTFE) yarn as the main sealing body, processed through a specialized braiding technique. This structure retains the high strength of aramid fibers while integrating the low friction, corrosion resistance, and excellent thermal conductivity of graphite PTFE, making it ideal for dynamic sealing in high-speed, high-pressure, and highly corrosive conditions

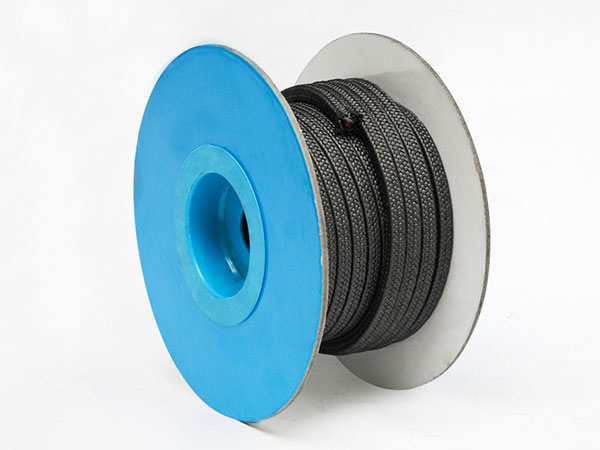

Graphite PTFE Packing with Aramid Fiber Corner

Description

PTFE Graphite Packing with Aramid Corner addresses the wear and heat issues of traditional sealing materials under high-pressure and high-speed conditions through innovative material composition and structural design. It is an ideal choice for industries such as petrochemicals, power generation, and pulp and paper. Its overall performance significantly reduces maintenance costs and enhances equipment reliability.

| Material | Graphite PTFE yarn, Aramid Fiber | |

| Temperature Range | -150 up to +280 oC | |

| Process | Rotating | 25 bar |

| Reciprocating | 150 bar | |

| Static | 200 bar | |

| Shaft Speed | 16m/s | |

| PH | 2~12 | |

| Density | 1.5g/cm3 | |

Feature

1. Reinforced Corner Design

The four corners are braided with PTFE-impregnated aramid fibers, significantly enhancing the braided packing’s resistance to extrusion and wear, suitable for high linear speeds (up to 15-20 m/s) in rotating equipment. and the high tensile strength of aramid fibers (≥3000 MPa) effectively prevents structural loosening under high pressure.

2. Sealing Body Material

The main body is braided with graphite PTFE (black PTFE) yarn, offering an extremely low friction coefficient, reducing shaft power loss; Superior thermal conductivity (due to graphite filling), rapidly dissipating frictional heat to prevent sealing failure from heat buildup; Chemical inertness, resistant to strong acids, alkalis, and organic solvents.

3. Specialized Braiding Process

Multilayer staggered braiding technology tightly integrates the aramid corners with the graphite PTFE yarns, compensating for the insufficient lubricity of aramid fiber packing and enhancing the mechanical strength of pure PTFE packing, extending service life.

Application

Petrochemical Industry: Centrifugal pumps, reactor agitator shaft seals (e.g., sulfuric acid transfer pumps, alkali circulation pumps).

Power Industry: Boiler feedwater pumps, desulfurization system valves.

Pulp and Sugar Industry: Slurry pumps, cooking equipment rotary seals.

General Industry: Mixers, compressor stuffing boxes (especially for media containing fine particles).