LongSeal Expanded PTFE (ePTFE) gaskets are made from 100% PTFE material that has been expanded into a unique, strong, and porous material. This highly fibrous material retains all the remarkable properties of PTFE itself—such as excellent chemical stability (resistance to most chemicals), extremely low friction coefficient, wide operational temperature range, and permanent durability without aging. The multi-fiber structure of ePTFE gaskets provides exceptional toughness as a sealing material and fundamentally addresses the common issues found in other types of PTFE sealing materials, such as creep and cold flow. Compared to pure PTFE and modified PTFE gaskets, ePTFE gaskets offer significantly improved performance. They are also easy to cut, simple to install, and have a long service life, making them suitable for nearly all sealing applications.

Advantages of Expanded PTFE Gaskets:

1. Strong Environmental Adaptability

Expanded PTFE gaskets can safely operate within a wide temperature range of -200°C to 315°C. They are resistant to most chemicals, except molten alkali metals and free fluorine atoms, in environments with pH values from 0 to 14. These gaskets can withstand internal pressures up to 20 MPa and comply with FDA/USDA standards, making them ideal for use in industries that require non-toxic, non-carcinogenic, non-allergenic, and contaminant-free sealing products, such as food, brewing, feed, and pharmaceuticals.

2. Excellent Compressibility and Resilience for Superior Sealing Performance

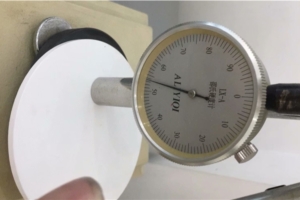

Expanded PTFE gaskets exhibit strong compressibility, typically achieving a compression ratio of 55% to 80%. This allows them to easily fill cracks, irregularities, voids, and grooves on sealing surfaces, thereby preventing leakage. Additionally, these gaskets have a rebound rate of 15% to 20% when under tension, meaning that as internal pressure increases, the sealing force of the gasket also increases. This characteristic is key to their outstanding sealing performance.

3. Easy to Handle and Install

The soft and easy-to-cut nature of expanded PTFE gaskets allows for simple installation. They can be cut to any desired length and size using mechanical or manual methods. Once the gasket is in place and external pressure is applied, the internal fibers compress and intertwine, forming a seal that conforms to the shape of the flange or pipe. This adaptability ensures a reliable seal, even on vertical flanges or suspended pipelines, without requiring additional clamping force, thereby extending the service life of the flange.

4. Resistance to Acid and Alkaline Corrosion and Aging

In addition to the chemical resistance and non-aging properties of standard PTFE gaskets, expanded PTFE gaskets offer enhanced resistance to creep and cold flow. They can be used safely over a wide temperature range (-200°C to 315°C) for extended periods, with a service life more than seven times that of conventional rubber and plastic sealing products.

5. Excellent Gas Barrier and Anti-Leakage Properties

Expanded PTFE gaskets have a fine, dense structure with very low gas permeability, which helps prevent the leakage of gases and water vapor. Their good compressibility ensures a tight fit on sealing surfaces, further enhancing their sealing performance.

6. Clean and Hygienic

Made from 100% virgin PTFE, expanded PTFE gaskets are non-toxic, non-polluting, and resistant to aging. This cleanliness ensures that they do not cause cross-contamination, maintaining the purity of the medium they are sealing and keeping the contact surfaces of flanges and pumps clean.

7. Economical and Practical

Expanded PTFE gaskets do not require pre-fabrication. They can be cut on-site to any shape, diameter, or cross-sectional area needed for flanges, structural gaskets, and packing, reducing the need for pre-designed gasket forms. This flexibility lowers the cost of design, procurement, and inventory. When the medium pressure is low and the gasket is intact, expanded PTFE gaskets can even be reused.

8. Exceptional Mechanical Compensation

The bidirectional dense fiber structure of expanded PTFE gaskets provides them with high elasticity before external force is applied. Once compressed, the fibers interlock, forming a solid material that is well-balanced, with low permeability to gases and fluids. This structure gives the gaskets excellent compressibility (typically 55% to 80%) and resilience (rebound rate of 15% to 20%), allowing them to effectively fill irregular sealing surfaces and compensate for mechanical imperfections on flanges, such as corrosion, scoring, or wear.

LongSeal expanded PTFE gaskets are ideal for sealing various fluids under demanding conditions, including strong acids, strong bases, gases, solvents, hydrocarbons, water, chlorine, aluminum fluoride, and hydrogen peroxide. They have proven effective in industries such as petrochemicals, caustic soda, chlor-alkali, and shipbuilding.

Suitable Equipment for Expanded PTFE Gaskets:

expanded PTFE gaskets are used for sealing flanges in pipelines, valves, pumps, pressure vessels, heat exchangers, condensers, generators, air compressors, exhaust pipes, refrigeration units, and more. They are especially suitable for sealing complex geometries, uneven flange surfaces, and special flanges like those with glass linings.

Applicable Industries of Expanded PTFE Gaskets:

expanded PTFE gaskets are widely used in chemical, petrochemical, refining, chlor-alkali, acid manufacturing, fertilizer, pharmaceutical, pesticide, synthetic fiber, dyeing, coking, gas, organic synthesis, non-ferrous metallurgy, steel, nuclear energy, and high-purity product manufacturing (such as ion membrane electrolysis). They are also ideal for handling viscous materials and for applications in food and beverage processing industries with strict hygiene requirements.

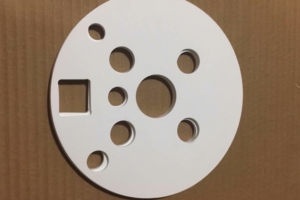

We can provide expanded PTFE gaskets in any standard, including ASME, DIN, JIS, GB, etc. Additionally, we offer round, square, and customized Non-standard gaskets, as well as reinforced strip-type ePTFE gaskets according to your needs