| Place of origin: | China |

| MOQ: | 20 pcs |

| Production capacity : | 10000-15000pcs/Month |

| Delivery time: | 3-5 days generally after getting the deposit |

| Package: Carton. | Or put in the plywood case for bulk quantity |

| Certificate: | Rohs, FDA, SGS, TUV |

| Material: | virgin PTFE resin(Modified PTFE mixed with glass fibre, etc power) |

| feature: | new type environmental material |

| Usage: | non-corrosive, non-pollution sealing application |

PTFE has excellent dielectric properties and provides excellent thermal insulation properties, and the operating temperature range is -400°F to 500°F. PTFE is the most chemically resistant plastic known and is not affected by most corrosive liquids, vapours and gases. PTFE is usually offered in thicknesses ranging from .002″ to .250″ and meets FDA and AMS specifications, making it acceptable for the medical and food production industries.

In a strong chemical environment, contamination of the medium is not allowed, and the use of standard gaskets is very complicated. Here PTFE gasket is used as a flange gasket connection. For example, in the (petro) chemical industry, in the process industry. The PTFE gasket is also very suitable for applications in the food industry. PTFE is physiologically inactive and can be used in direct contact with food.

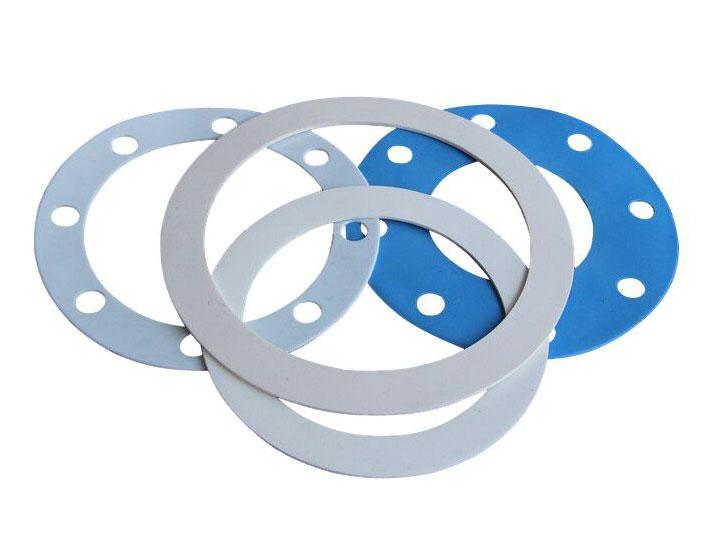

Longseal supplies high-quality PTFE gaskets, including expanded PTFE gasket, modified PTFE gasket, PTFE bonded EPDM gasket, pure PTFE gasket.

Expanded PTFE Gasket

Expanded PTFE Gasket is cut from Expanded PTFE gasket sheet, our expanded PTFE gasket sheet made with only pure PTFE resins. It is suitable for use in steel flanges as well as flanges where a highly compressible gasket is required. Expanded PTFE Gasket is also suitable for sealing flanges with irregular surfaces. It will not exhibit the cold flow problems associated with virgin PTFE or the hardness problems of some other filled PTFE products. It has excellent sealability, cuts easily, and separates cleanly from flanges after use

Modified PTFE Gasket

The Modified PTFE for use as a gasket material with strong chemical resistance properties and designed for severe chemical service, colour-coded for easy identification, superior seal-ability, which helps reduce process and media loss as well as fugitive emissions, reduced creep, and cold flow characteristics. The different combination offers a variety of different properties as the following sheet.

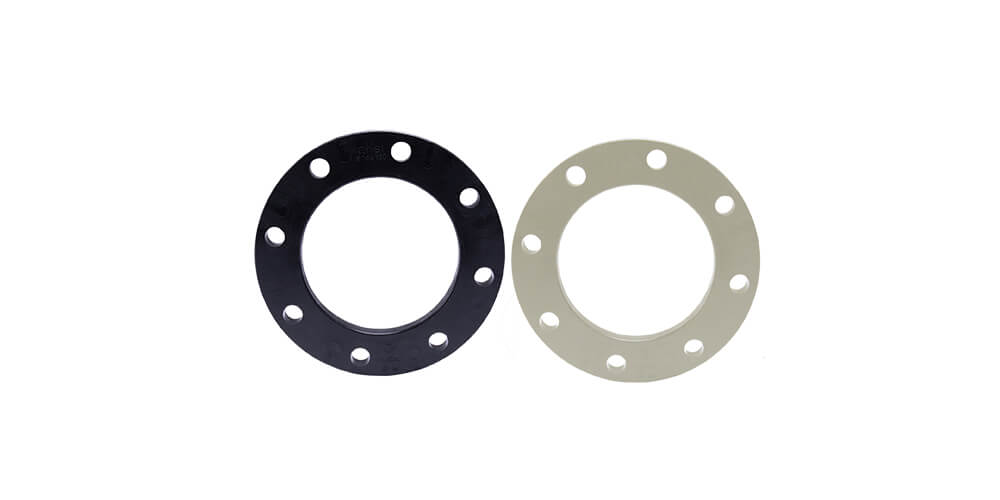

PTFE Bonded EPDM Gasket

PTFE Bonded EPDM gasket is produced with high-quality EPDM rubber and PTFE for maximum chemical and corrosion resistance. They are suitable for fibreglass, glass-lined, and steel full-face flanges. The gaskets have Low bolt torque with superior sealing, Dual, Concentric, Convex sealing rings; They will eliminate cracked flanges, reducing installation costs, while maintaining high performance. It is ideal for plastic piping systems, as well as metal or plastic-lined metal systems. Standards: ASME (ANSI) B16.5, JIS 10K, DIN2501 PN10/PN16, SABS1123, BS4504 etc

Pure PTFE Gasket

Pure PTFE Gasket is moulded or skived or cut from virgin PTFE sheets, rods, tubes or compounds etc. It has the best chemical corrosion resistance among known plastics. Without being ageing, lowest friction coefficient, wear resistance. The unloaded operating temperature range is -180~+260C.

PTFE Gaskets Manufacturers FAQ

1. What is a PTFE gasket?

A PTFE gasket is a gasket made from a synthetic fluoropolymer of tetrafluoroethylene composed entirely of carbon and fluorine. It is inherently hydrophobic (repelling water and water-containing substances) and has one of the lowest friction coefficients compared to other types of gaskets. Due to its excellent dielectric properties and excellent thermal insulation in the operating temperature range of -200°C to 260°C, PTFE gaskets are known to be the most chemically resistant gaskets from most corrosive liquids, vapors, and gases. Therefore, it has a wide range of applications, including product sealing and content filling. It is often used in bridge bearings, bearing building stairs, eliminating heat bilges cold shrink, and unexpected vibration, such as seismic load migration, security, bridges, and buildings.

2. What are the characteristics of PTFE gaskets?

PTFE gaskets have many unique features:

- Excellent chemical resistance.

- Non-humid, non-polluting, and odorless.

- Works efficiently at low temperatures up to 260°C.

- Has excellent electrical insulation and thermal insulation properties.

- High melting point

- High surface wear

- High elasticity

- Flexibility

- Inert to most chemicals and solvents, it is resistant to strong acids, alkalis, aqua regia, and a variety of organic solvents.

- Weather Resistant – Has the best aging life of any plastic.

- Among solid materials, high lubrication has the lowest coefficient of friction.

- Non-stick – It is the smallest surface tension in a solid material that does not stick to anything.

- Artificial blood vessels and organs that are non-toxic and can be implanted into the body for an extended period of time without causing any adverse reactions.

3. What are the advantages and disadvantages of PTFE gaskets?

Advantages of PTFE Gaskets

Due to its unique features, a PTFE gasket has many advantages that other materials of the same functions may fail to provide. Here are some of its most distinctive advantages.

- Corrosion resistance

When specifying gasket materials, chemical compatibility is usually one of the first things to check. Machines that are not compatible with typical rubber compounds, or aggressive chemicals, make PTFE gaskets the best choice material to reduce erosion.

PTFE is immune to virtually all industrial chemicals, making it one of the most corrosion-resistant materials in any industry. This also means that PTFE gaskets made of PTFE can be widely used.

- Long shelf life

Applications requiring long life or extended service intervals in corrosive environments can also use PTFE gaskets. PTFE does not degrade with aging and is not affected by UV light, so controlled aging is usually not required for PTFE gaskets.

While some elastomers may survive short-term or intermittent exposure, degradation over time can cause problems years later, while the resistance properties of PTFE gaskets will remain indefinitely.

- Wide temperature range

The temperature range of PTFE from -325°F to +500°F is also well beyond the range of most elastomers. Therefore, PTFE gaskets are indeed an excellent material for high-temperature environments.

Most rubber compounds will harden to the point where they no longer have any elastomeric properties at extremely low temperatures. This combined shrink material may mean that it will no longer function effectively as a seal.

- PTFE, on the other hand, remains bendable and flexible even at low temperatures.

- PTFE gasket will not expand due to moisture absorption

- PTFE gasket is not easy to explode and decompress

Disadvantages of PTFE gaskets

While chemical attacks or extreme temperatures may not leave any option other than PTFE, there are some disadvantages of this material that may affect your project.

- High hardness

Higher hardness has a negative impact on sealing, as the material does not easily conform to mating hardware surfaces.

- Leak rate

PTFE gaskets may require later surface finish improvements to control leakage to acceptable levels.

In general, PTFE gaskets will have a higher leak rate than any elastomer compound under normal conditions.

- No elasticity

The properties of PTFE as a non-elastic material mean that reuse or repeated installation of the same seal will not be possible.

Unlike rubber compounds, PTFE does not return to its original shape and cross-section once deformed during installation and use. This means that PTFE gaskets are generally only recommended for static face seal or flange type configurations, with no active engagement and disengagement. For example, PTFE gaskets are not recommended for hatch door seals that require frequent opening and closing, as the gasket may need to be replaced after each use.

Re-used PTFE gaskets may look and perform similarly to standard gaskets subjected to extreme compression. But unlike rubber, this set of compression-only happens after one use. More commonly, PTFE gaskets are used in flanged gasket-type applications where the seal will remain static and undisturbed until the next use interval.

4. What are the applications of PTFE gaskets?

Due to the characteristics of the raw material PTFE, PTFE gaskets have been widely used. Here are some of the most common areas that require PFTE gaskets.

- Petrochemical industry

PTFE gaskets are widely used in chemical equipment due to their high resistance to corrosive fluids and chemicals. With the exception of certain alkali metals and fluorine compounds, PTFE has high corrosion resistance to almost many chemicals at different temperatures and pressures.

- Pharmaceutical Industry

PTFE is mainly used in the pharmaceutical and medical device industries. During pharmaceutical production, the process involves high surface wear and PTFE can withstand it. The properties of PTFE such as high temperature and chemical resistance ensure the safety of industrial sealants.

PTFE gaskets help prevent contamination of pharmaceuticals during production.

- Electrical industry

PTFE gaskets can also be used to manufacture sealing gaskets for motors, transformers, and various high-heat and high-wear electrical appliances. It is also used in electronic instruments to make safety seals and increase product life.

- Food processing industry

PTFE gaskets are manufactured to FDA and AMS standards. Polytetrafluoroethylene (PTFE), a commonly used multifunctional high-performance fluoropolymer, consists of long chains of carbon and fluorine atoms that do not allow it to combine with other substances, making it the best material for food processing plants.

- Compressor

High temperature resistant, suitable for compressor applications.

5. What is the price of a PTFE gasket?

The price of a PTFE gasket typically ranges from a few cents to several dollars, depending on its size and production procedure. Prices may vary a little bit as customers usually buy in bulk.

6. What do you need to pay attention to while using a PTFE gasket?

- The sealing line or sealing surface on the surface of the PTFE gasket seal shall not be damaged. The flat PTFE gasket seal can rely on the upper and lower end faces; the sealing performance of the hydraulic PTFE gasket seal is mainly through the lip line associated with the shaft or hole, these parts are made of soft and resilient. Corrosion-resistant, temperature-resistant, aging-resistant graphite, fiber, rubber, and plastic are made of special materials that are vulnerable to damage, so special care must be taken during installation, handling, and storage. Once damaged, it will bring great damage to the sealing part.

- During the installation process, do not force too much action, which will damage the original prefabricated structure of our PTFE gasket seal. So we have to be very careful when installing the PTFE gasket seal, and the embedding step must be done step by step.

- The installation of PTFE gasket seals must follow symmetry and balance. Place the PTFE gasket seal just enough to catch the lip face (or effective sealing face) during installation. After the system is put into use, it is necessary to continuously observe and do the follow-up work of the PTFE gasket seal, so as to prevent the collapse caused by micro-leakage caused by the change in working conditions (such as pressurization) during the working process of the system.

7. How to store PFTE gaskets?

Although PTFE is a highly resistant material, it still requires careful preservation to keep its lifespan as long as possible. Here is something you need to pay attention to while storing the PTFE gasket.

- Gasket material should be stored in a cool, dry place. Avoid storing materials in direct sunlight or near heaters. Avoid contact with water, oil, or chemicals. Gaskets should not be stored lest they be damaged by sealing too tightly.

- Aging is a factor that should be considered. However, the age of each material is different.

- Compressed material will last 3-5 years under normal storage conditions. Filled Teflon and flexible graphite can be stored indefinitely.

- All processes that generate dust, such as drilling, grinding, and sawing, should not be used for gasket materials.

- Follow special instructions for any equipment or fluids that require sealing: for example, oxygen service or low chloride requirements.

- Avoid hanging the washer on nails or nails, as this can cause the washer to deform. When storing racks or bins of gasket material, the material should be rotated, placing the old material in the front or top and the new material in the back or below.

- All gasket materials should be identified (branded) to prevent misuse. Washers should be properly labeled to ensure there is no confusion between different grades and/or sizes.